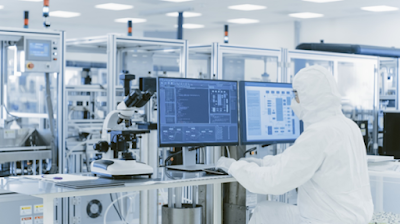

The pharmaceutical industry has been undergoing a massive overhaul. There’s a paradigm shift that is going on, to further improve productivity and quality. And the Pharma 4.0 initiative is the benchmark that the industry is trying to gradually upgrade to.

Through digitalization and the use of smarter tools and processes, Pharma 4.0 is expected to not only improve productivity but also ensure better quality and save time and costs, among several other benefits.

ISPE (International Society for Pharmacoepidemiology) is in the process of developing the roadmap to introduce Industry 4.0 to the pharmaceutical industry as Pharma 4.0.

What is Pharma 4.0?

Developed in 2017, Pharma 4.0 is an ISPE initiative that aims to improve the processes throughout the life cycle of pharmaceutical products with the help of modern smart technology.

It aims to do so by aligning the pharmaceutical industry with the philosophy of Industry 4.0. Read more.....

Source Link:- https://www.pharmision.barcodeindia.com/blogs/how-pharma-4-0-will-revolutionize-the-pharmaceutical-industry/